|

Vacation Week 11/29/2004Day 1: Restored good even compression.!!! Finished lapping all the valves. The exhaust valve seats were the most damaged by pitting. Spent a good 4+ hours working with a hand lapping tool. Reassembled the valves and installed the head utilizing the old gasket so that I could check the compression. A dry test pumped up 45 psi. in each cylinder. Since I had zero to start with this is very significant and will do much better under wet or running conditions. Day 2... I will be installing a new head gasket and moving on to other engine areas.

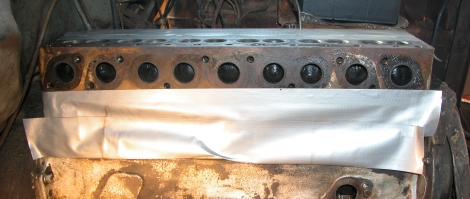

The Lapping Process: I removed all the valves and springs and placed each set in a numbered bag. It is important to keep all parts in order and return them to the same place that they were removed from. I utilized Duct Tape to cover the cylinders. It is important to keep the lapping compound away from other engine parts. When I finished with each valve I removed the valve and washed it in water, dried and oiled it. I then inserted a suitable bolt into the valve stem to plug the hole so that lapping compound wouldn't find its way into the engine. Lapping compound has fine granite or diamond dust in the paste, not something you want floating around in your engine lubricating oil. |

| Once the lapping process was completed and a good seal was recreated between the valves and seats, you need to wash the area to remove all the excess lapping paste. By duct tapping the valve adjustment compartment and the cylinder heads you may wash the area with water and use compressed air to dry. After the water has dried spray all metal parts with lubricant and reassemble your valves and springs. |

|