Basically if you can find a shop that can still clean out the radiator and solder any leaks then you should be good to go. Flush out the motor to get as much crap out as possible. Are you doing any engine work ?

- Welcome to 28Q29U Plymouth Forum.

News:

NEW FORUM version is here.

If you are experiencing any problems, contact chetbrz@aol.com

WELCOME Auto Registration is turned OFF.

In order to register for this forum please contact chetbrz@aol.com to request access.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

#1172

General Discussion / Re: water pump

February 20, 2015, 08:21:57 AMIf you have the original capacity radiator you shouldn't need a water pump. The thermal-syphon system works well even in 98 degree summer temperatures. I don't believe anyone sells an electric water pump for automotive purposes ? But I could be wrong.

Chet...

#1173

General Discussion / Re: Dave's 1929 U Resto project

February 18, 2015, 10:54:49 AM

Dave,

I think you have the right idea. Looking at a factory fresh 1920's car is a curiosity but I must say that I am drawn to that beat up old survivor that shows real character. You can almost picture all the hard times and years that the car and its owners have gone through. My car on the other hand has been poorly restored many years ago and needs to be redone. I will try to keep as much of it original and leave the old interior. I guess once I get into it.., the work will decide where it needs to go. Mechanical reliability is a must.

As far as the wiring harness goes I know somebody makes it and it has been discussed on this site so hopefully someone will chime in with the vender info.

Chet...

I think you have the right idea. Looking at a factory fresh 1920's car is a curiosity but I must say that I am drawn to that beat up old survivor that shows real character. You can almost picture all the hard times and years that the car and its owners have gone through. My car on the other hand has been poorly restored many years ago and needs to be redone. I will try to keep as much of it original and leave the old interior. I guess once I get into it.., the work will decide where it needs to go. Mechanical reliability is a must.

As far as the wiring harness goes I know somebody makes it and it has been discussed on this site so hopefully someone will chime in with the vender info.

Chet...

#1174

General Discussion / Re: 28 Q U-Joints

February 18, 2015, 08:09:47 AMQuote from: ski on February 17, 2015, 06:29:00 PM

Mine are cotter pinned so I think as tight as the disc material can handle would be the limiting factor. I snugged mine good and went to the next hole being careful.

ski

I agree with ski, hand tight should work fine. For safety, you want to use bolts that have carter pin holes.

Chet...

#1175

General Discussion / Re: Dave's 1929 U Resto project

February 18, 2015, 08:00:28 AM

Hi Dave,

It looks like you are moving along. Just a couple of questions about your project.

On the rewire are you going to use a premade harness and are you going to wire in turn signals?

Is your restoration focused on originality or functionality and safety?

Hopefully I can finally start on my this summer. I haven't decided yet where I am going to draw the line.

Chet...

It looks like you are moving along. Just a couple of questions about your project.

On the rewire are you going to use a premade harness and are you going to wire in turn signals?

Is your restoration focused on originality or functionality and safety?

Hopefully I can finally start on my this summer. I haven't decided yet where I am going to draw the line.

Chet...

#1176

General Discussion / Re: Time to Get Into the Motor - Part 2 (Update)

February 08, 2015, 07:07:10 PMQuote from: racertb on February 08, 2015, 02:54:07 PM

On a side note, it was mentioned earlier on that it looks like my housing was once repaired or modified. The housing itself is good, but I just noticed that someone added a brass or bronze sleeve where the drive itself rotates. A zerk fitting for grease was also added to the housing right where the drive is. I think some added grease will also take up some slack.

Ted,

It sounds to me that the brass sleeve was installed to fix an oblonged drive shaft hole. Brass was probably used so as not to cause anymore wear to the steal drive shaft. The brass sleeve has probably gone the way of the original drive hole. May be time to check the concentricity of the hole the drive shaft turns in. Is the shaft removable without damaging the assembly ?

Chet...

#1177

General Discussion / Re: 28Q photos

February 07, 2015, 08:01:35 AM

If you use a free online service like Photobucket ( http://photobucket.com/ ) you can post or point a link to your photo album.

#1178

General Discussion / Re: Clum Light Switch

February 06, 2015, 12:58:07 PMQuote from: frankp on February 06, 2015, 10:53:40 AM

Hi Chet,

Here's my info for the wiring.

http://www.1948plymouth.info/28Q29U/index.php?topic=862.msg5321#msg5321

frank

Frank,

I think you are both saying the same think just the numbering is different:

Numbered from the engine to fender:

Yours = 1 - 3 - 2 - 4 - 6 - 5

OldMans = 1 - 2 - 3 - 4 - 5 - 6

Other than that you are both saying the same thing. I don't recall if my switch had numbers written on it but the third post that you are referring to as '2' and Oldman is referring to as '3' are the same. On my switch this post is broken off and the horn wire is tied to chassis ground. I believe we have the same conflict with points 5 & 6. Not a big deal, minor inconsistency as to just how they are being logically referenced.

Chet...

#1179

General Discussion / Re: Clum Light Switch

February 06, 2015, 08:58:21 AM

Rich & Oldman,

Can you both review the diagrams and explanations. I believe terminals 2 & 3 might be mislabeled on Rich's diagram. I believe terminal #3 gets it's grounding from the wire running from the horn. (As stated in Oldman's description, #3 is a tie point)

I would like to combine these two explanations and drawings into a single document. I believe they are both showing the correct information.

Oldman, See Rich's document... http://www.1948plymouth.info/28Q29U/index.php?action=dlattach;topic=433.0;attach=915

Please review, Tks Chet...

Can you both review the diagrams and explanations. I believe terminals 2 & 3 might be mislabeled on Rich's diagram. I believe terminal #3 gets it's grounding from the wire running from the horn. (As stated in Oldman's description, #3 is a tie point)

I would like to combine these two explanations and drawings into a single document. I believe they are both showing the correct information.

Oldman, See Rich's document... http://www.1948plymouth.info/28Q29U/index.php?action=dlattach;topic=433.0;attach=915

Please review, Tks Chet...

#1180

General Discussion / Re: 28 Q questions

February 01, 2015, 06:14:02 PM1) Three discs go on the differential end and two go on the transmission end of the drive shaft.

#1181

General Discussion / Re: Time to Get Into the Motor - Part 2 (Update)

February 01, 2015, 03:15:29 PMQuote from: racertb on February 01, 2015, 02:34:21 PM

Guys, I know and understand the concept of backlash and that things can't be so tight that they'll bind. My main question with what I found, along with the photos and videos previously posted, is it showing too much play? It seems too much to me, but I'm not 100% sure.

Ted

Ted,

No one is ever 100% sure. If it seems like the assembly has to much play and you can do something to lessen it then do try it and see if it helps. Troubleshooting a problem is the same as solving a mystery and this is done by eliminating suspects. Your distributor assembly is just one suspect. If the assembly is not capable of skipping a tooth and going out of time than you need to move on to your next logical suspect. I think the problem you are having is you can't seem to definitively say whether the assembly is good or bad. Without that determination you can't move forward in the troubleshooting process. I don't believe anyone can remotely make that determination for you.

Fix what appears to be a problem, after all even if it isn't causing a problem making something a little better is never a bad thing. Eliminating a suspect is always good.

Chet...

#1182

General Discussion / Re: Time to Get Into the Motor - Part 2 (Update)

February 01, 2015, 09:05:10 AM

Ted,

All gears need some amount of play, it's called backlash.

Backlash as it refers to gears is "the difference between the thickness of a gear tooth and the width of the space between teeth in the mating gear, designed to allow room for lubricants and expansion. Backlash sometimes describes play or lost motion between loosely fitting machine parts.

What Jeff and others have been asking you to check is when the play in both the drive shaft and distributor are at their greatest distances simultaneously from each other. Can you turn the drive assembly or distributor and get the gears to skip a tooth. ?

When you answer this question you can eliminate all doubt as to what your problem is. We can't make that call in an email or posted message. BTW.., What can increase backlash is worn gear shafts or oblonged bearings or shaft pivot holes.

Chet...

All gears need some amount of play, it's called backlash.

Backlash as it refers to gears is "the difference between the thickness of a gear tooth and the width of the space between teeth in the mating gear, designed to allow room for lubricants and expansion. Backlash sometimes describes play or lost motion between loosely fitting machine parts.

What Jeff and others have been asking you to check is when the play in both the drive shaft and distributor are at their greatest distances simultaneously from each other. Can you turn the drive assembly or distributor and get the gears to skip a tooth. ?

When you answer this question you can eliminate all doubt as to what your problem is. We can't make that call in an email or posted message. BTW.., What can increase backlash is worn gear shafts or oblonged bearings or shaft pivot holes.

Chet...

#1183

General Discussion / Re: Time to Get Into the Motor - Part 2 (Update)

January 25, 2015, 07:28:26 PM

Ted,

With the distributor in the assembly how much end play is in the assembly drive and if you max out the end play in the distributor as well as the drive assembly can you get the unit to slip a tooth or bind ? Any gear system should have some end play but it should not be excessive.

Can you put a slotted screwdriver into the motor and check how much play there is in the drive assembly in the block.

It's hard to tell if there is a problem without actually touching and feeling these parts. How is the internal drive shaft in the assembly and the inner assembly drive gear. My assumption is no chipped teeth ?

What is that ring being used for does it hold the drive key in place on the shaft ? If you took the pin out what would be removed and what would the purpose be to remove the pin ?.

Just some food for thought.

With the distributor in the assembly how much end play is in the assembly drive and if you max out the end play in the distributor as well as the drive assembly can you get the unit to slip a tooth or bind ? Any gear system should have some end play but it should not be excessive.

Can you put a slotted screwdriver into the motor and check how much play there is in the drive assembly in the block.

It's hard to tell if there is a problem without actually touching and feeling these parts. How is the internal drive shaft in the assembly and the inner assembly drive gear. My assumption is no chipped teeth ?

What is that ring being used for does it hold the drive key in place on the shaft ? If you took the pin out what would be removed and what would the purpose be to remove the pin ?.

Just some food for thought.

#1184

General Discussion / Re: Time to Get Into the Motor - Part 2 (Update)

January 25, 2015, 08:48:06 AM

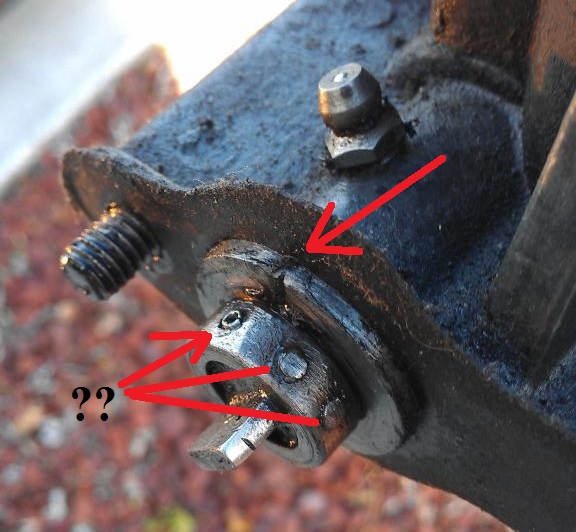

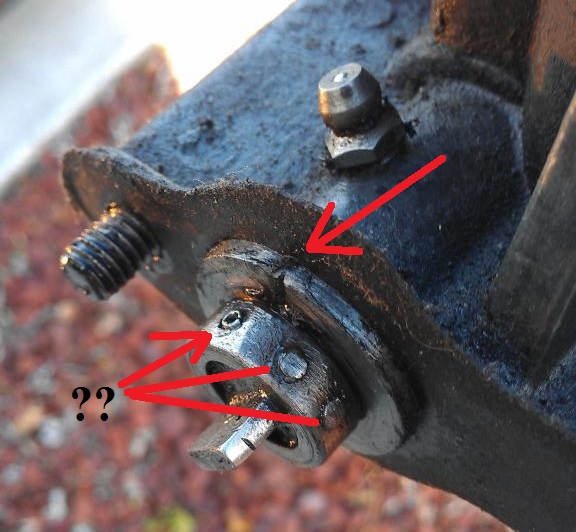

Questions:

Why is the locating collar split and if you remove the mounting gasket is the flange cracked ?

Why does the ring around the distributor appear to have two pins and a setscrew (or scroll pin) ? This seems excessive or a previous repair ?

My engine doesn't have the original pot metal piece so have patience with the questions ?

Chet...

Why is the locating collar split and if you remove the mounting gasket is the flange cracked ?

Why does the ring around the distributor appear to have two pins and a setscrew (or scroll pin) ? This seems excessive or a previous repair ?

My engine doesn't have the original pot metal piece so have patience with the questions ?

Chet...

#1185

General Discussion / Re: Windshield weatherstripping Rubber

January 23, 2015, 03:18:03 PM

Frank,

You're correct. This is why I don't remember needing any parts. Actually pretty easy install.

John, here is a link to the windshield set:

http://www.steelerubber.com/search?year=1929&make=plymouth&model=model-u&style=4-door-sedan-5-passenger&q=Windshield+Weatherstrip+Seal

You're correct. This is why I don't remember needing any parts. Actually pretty easy install.

John, here is a link to the windshield set:

http://www.steelerubber.com/search?year=1929&make=plymouth&model=model-u&style=4-door-sedan-5-passenger&q=Windshield+Weatherstrip+Seal