The Motor Continued...

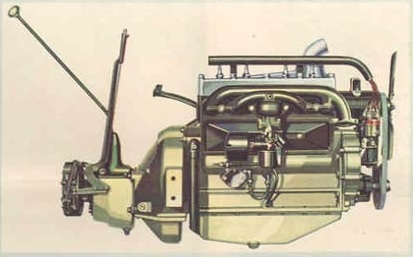

I delivered the motor safe and sound to J&M Machine in Southborough, Massachusetts. They keep a Facebook Page and will be sharing photos of the rebuild in progress. If anyone is interested the link is below and you do not have to be a Facebook member to view the pictures. John reports that the pistons are the original stock size. My assumption is that this is the first major rebuild.

https://www.facebook.com/pg/J-and-M-Machine-Co-Inc-270076059772640/photos/?tab=album&album_id=1467684380011796

The weather has turned a little cold but I have still been making progress. I sent out my Original Generator and Starter motor to Don Allen in Florence, Oregon. Don was featured on JAY LENO'S GARAGE. Don will be completely restoring these parts to original like new condition. This includes rewinding and wiring both the Generator and Starter motor with all new parts. A "like new" engine deserves a "like new" Generator and Starter. Below is a link to Don's web site.

https://www.gener-nator.com/index.htm

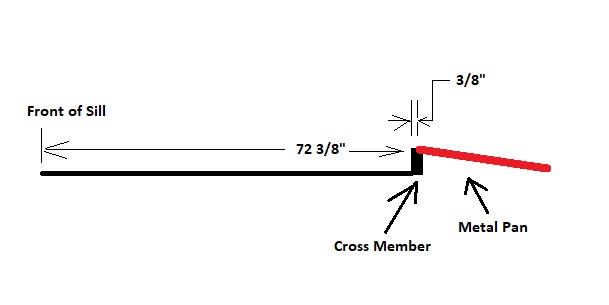

Neither one of these processes are inexpensive and just my personal choice. Currently I am waiting for the wiring harness so if the weather gets better I will start on cleaning up the front frames and engine firewall. Of course working on the toe board will be a lot easier without the engine.

Happy Holidays, Chet...

I delivered the motor safe and sound to J&M Machine in Southborough, Massachusetts. They keep a Facebook Page and will be sharing photos of the rebuild in progress. If anyone is interested the link is below and you do not have to be a Facebook member to view the pictures. John reports that the pistons are the original stock size. My assumption is that this is the first major rebuild.

https://www.facebook.com/pg/J-and-M-Machine-Co-Inc-270076059772640/photos/?tab=album&album_id=1467684380011796

The weather has turned a little cold but I have still been making progress. I sent out my Original Generator and Starter motor to Don Allen in Florence, Oregon. Don was featured on JAY LENO'S GARAGE. Don will be completely restoring these parts to original like new condition. This includes rewinding and wiring both the Generator and Starter motor with all new parts. A "like new" engine deserves a "like new" Generator and Starter. Below is a link to Don's web site.

https://www.gener-nator.com/index.htm

Neither one of these processes are inexpensive and just my personal choice. Currently I am waiting for the wiring harness so if the weather gets better I will start on cleaning up the front frames and engine firewall. Of course working on the toe board will be a lot easier without the engine.

Happy Holidays, Chet...

--

--