- Welcome to 28Q29U Plymouth Forum.

News:

NEW FORUM version is here.

If you are experiencing any problems, contact chetbrz@aol.com

WELCOME Auto Registration is turned OFF.

In order to register for this forum please contact chetbrz@aol.com to request access.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

#2

General Discussion / Bugs and Pollen

April 24, 2023, 03:02:04 PM

The wife and I took out the 29 for a 22-mile run around the neighborhood. The fuel pump seems to be working properly and the brake light switch that Touring29 recommended installed and worked just fine.

Now if it doesn't rain this coming weekend, we will drive up to our nearby state park to meet up with our local car club. Now to attend to the Bugs & Pollen collected on our venture.

Cheers, Chet...

Now if it doesn't rain this coming weekend, we will drive up to our nearby state park to meet up with our local car club. Now to attend to the Bugs & Pollen collected on our venture.

Cheers, Chet...

#3

General Discussion / Brake Light Switch

April 13, 2023, 04:30:17 PM

Tried to get out to a club meeting with the 29 but have been working on things since yesterday. Long story for another time.

Question: I now have a bad brake light switch. When I change this do I have to bleed the lines? Has anyone experienced a switch not working and after bleeding the lines the problem corrects itself?

I did however fix a chronic problem with the Vaccuum fuel pump. The float would jam occasionally. Not anymore.

Question: I now have a bad brake light switch. When I change this do I have to bleed the lines? Has anyone experienced a switch not working and after bleeding the lines the problem corrects itself?

I did however fix a chronic problem with the Vaccuum fuel pump. The float would jam occasionally. Not anymore.

#4

General Discussion / 16 year Forum Anniversary

February 01, 2023, 10:27:25 AM

I created this forum 16 years ago in March of 2007. Back in those days the costs were minimal and I was also gainfully employed. For the last 8 of those 16 years I have been retired and costs have certainly increased while like most retirees my income has greatly declined. I am not sure if I will renew this site after February 2024. The increasing cost and needed security upgrades are getting a little pricy. I don't believe there is enough traffic to offset current costs by adding ads, but I'll check into it.

Just a very early FYI... on what might be a future problem.

Just a very early FYI... on what might be a future problem.

#5

General Discussion / Season's Greetings

December 21, 2022, 09:34:35 PM

A safe and Happy Holiday to all...

#6

General Discussion / Add Photos

November 27, 2022, 08:57:38 AM

To attach a photo, open the "Attachments and other options" and use the add files option.

You cannot view this attachment.

Upload and insert into your text.

You cannot view this attachment.

Remember upload and insert.

I hope this helps, Chet...

You cannot view this attachment.

Upload and insert into your text.

You cannot view this attachment.

Remember upload and insert.

I hope this helps, Chet...

#7

General Discussion / 29 Sedan Pin Striping

July 16, 2022, 04:09:05 PM

Does anyone have a picture that clearly shows the pin striping requirement for the 29U sedan?

False alarm..., I found what I needed. But any words of wisdom are always appreciated.

False alarm..., I found what I needed. But any words of wisdom are always appreciated.

#8

General Discussion / Nice Day for a Drive

June 20, 2022, 07:53:55 PM

Before I took the car out, I checked the universal disks. They looked the same as the day I first installed them in 2007. Drove about 30 miles round trip to a park near my house. Beautiful sunny day with temps in the high 70's. I have driven 260 miles since I did anything to the Vaccuum fuel pump. So, I guess that's working properly.

The car looks great but rides like a 93-year-old car. Likes 35mph but on one lane roads drivers get impatient so I pull off where I can, to ease their stress. I can't seem to find the right light to photograph this car because there are always reflections in either the glass or paint. The picture below is the best of the lot.

You cannot view this attachment.

The car looks great but rides like a 93-year-old car. Likes 35mph but on one lane roads drivers get impatient so I pull off where I can, to ease their stress. I can't seem to find the right light to photograph this car because there are always reflections in either the glass or paint. The picture below is the best of the lot.

You cannot view this attachment.

#9

General Discussion / First Drive 2022

May 23, 2022, 12:18:25 PM

This was the first opportunity I had to take the 29 out since I replaced the passenger side front wheel. I was amazed that after sitting all winter the car started on the first crank. Oil pressure came right back, and it was alive again. The wife and I drove about 15 miles round trip to get some gas at a local station. The ride was 100% better than before.., that old wheel must have been wobbling with the road surface. The car finally felt solid.

You cannot view this attachment.

Nice day in the neighborhood...

You cannot view this attachment.

Nice day in the neighborhood...

#10

General Discussion / Quiet Board

May 10, 2022, 07:52:15 PM

I guess everything is working fine. Dog sitting in Virginia hope to get the car out next week. The new respoked front wheel installed beautifully. Perfectly concentric and strong as it should be.

Now to work on nice to-do things and ongoing maintenance.

Now to work on nice to-do things and ongoing maintenance.

#11

General Discussion / @@@ Server Timeouts @@@

April 10, 2022, 10:15:44 AM

Lately we have been experiencing Server Timeouts. After investigating this problem, it doesn't seem to be associated with the new forum version. It may possibly be heavy usage experienced by the hosting service.

I have made changes to picture thumbnail size which might cause pages to load slowly the first time they are loaded after this change. This should decrease as time goes on. I will continue to seek information on how best to keep this forum as current and operating as efficiently as possible.

Feel free to email me if you are experiencing connection problems. If possible, a screen shot of the reported error code or message.

Tks, Chet...

I have made changes to picture thumbnail size which might cause pages to load slowly the first time they are loaded after this change. This should decrease as time goes on. I will continue to seek information on how best to keep this forum as current and operating as efficiently as possible.

Feel free to email me if you are experiencing connection problems. If possible, a screen shot of the reported error code or message.

Tks, Chet...

#12

General Discussion / Season's Greetings

December 18, 2021, 02:04:50 PMMerry Christmas & Happy New Year

To All !!!

To All !!!

#13

General Discussion / @@@ Happy Thanksgiving @@@

November 22, 2021, 09:12:09 AM

I hope you all have a Great Holiday. Thanks for all the help over the years !!

#14

Things you are looking for. / Split Rim

November 03, 2021, 09:07:02 AM

Does anyone know where I might find a 19" Split Rim that I can use for a spare tire ? Having one custom made is very costly.

#15

General Discussion / Split Rim Question

October 31, 2021, 12:58:59 PM

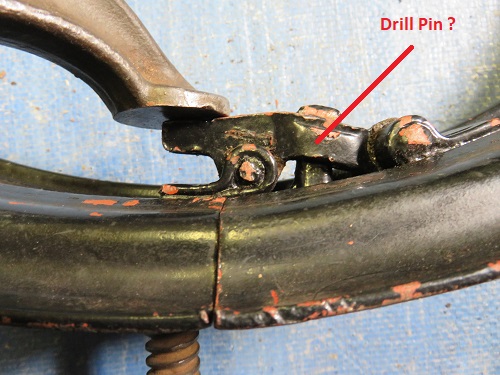

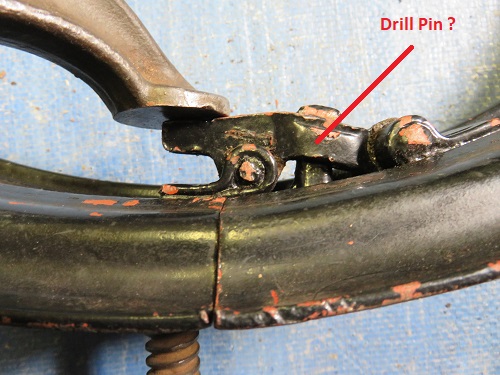

I removed one of the old Allstate tires from its split rim. Quite a job. The tire was petrified and I had to cut it with a jig saw in order to pry it off the split rim. So much for complaining. My problem is that the split rim opened fine but doesn't want to reclose.

I was thinking of drilling a hole to install a pin ?? Any tricks I am missing ?

I didn't want to hammer the post in fear that it might break the mounting rivet.

Any Suggestions.

I was thinking of drilling a hole to install a pin ?? Any tricks I am missing ?

I didn't want to hammer the post in fear that it might break the mounting rivet.

Any Suggestions.

#16

General Discussion / Hub Nut Question

October 29, 2021, 10:56:39 AM

Does anyone know where to purchase the nuts that hold the brake drum to the wood wheel.

They are 3/8 X 16 and are about 1/4" thick and oversized. The standard 3/8 x 16 nut uses a 9/16 socket these hub nuts are 3/8 x 16 and use an 11/16 socket. Two sizes bigger ? Are these Jam Nuts ?

They are 3/8 X 16 and are about 1/4" thick and oversized. The standard 3/8 x 16 nut uses a 9/16 socket these hub nuts are 3/8 x 16 and use an 11/16 socket. Two sizes bigger ? Are these Jam Nuts ?

#17

General Discussion / Nice Day for a Drive

October 19, 2021, 04:18:10 PM

Haven't done much to the cars these days but couldn't resist a drive today. Only went about 14 miles to Abbotts Pond nature trail took a lot of pictures but the one below was the best of the bunch.

The car started right up even after sitting for 2.5 months. Still using the vacuum fuel pump without any problems.

Chet...

The car started right up even after sitting for 2.5 months. Still using the vacuum fuel pump without any problems.

Chet...

#18

General Discussion / Running Board Question

May 12, 2021, 03:25:47 PM

What type of hardware was used to attach the running board to the frame supports.

or

What did you use to secure the boards.

Tks Chet...

or

What did you use to secure the boards.

Tks Chet...

#19

General Discussion / Brake Shoes

May 09, 2021, 03:58:23 PM

Anyone here tried these reproductions...

https://www.moparpro.com/product/1929-1934-plymouth-brand-new-reproduction-10-x-1-5-brake-shoes/

I have a set of 4 that I was going to send out and have relined. A set of 4 new for $135 seems reasonable.

Any thoughts ?

https://www.moparpro.com/product/1929-1934-plymouth-brand-new-reproduction-10-x-1-5-brake-shoes/

I have a set of 4 that I was going to send out and have relined. A set of 4 new for $135 seems reasonable.

Any thoughts ?

#20

General Discussion / 2021 Drive

May 06, 2021, 04:47:22 PM

I took the old car out for the first time since December. She started right up no problems. Drove about 22 miles around the neighborhood. That makes 113.5 driven miles on my rebuilt engine. Also 4.8 hours of runtime since I primed the Vacuum fuel pump. The car may be running a little rich something I will fine tune over the summer.