Thanks for the info.

Chet...

Chet...

NEW FORUM version is here.

If you are experiencing any problems, contact chetbrz@aol.com

WELCOME Auto Registration is turned OFF.

In order to register for this forum please contact chetbrz@aol.com to request access.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

Quote from: 29UJohn on December 17, 2017, 03:51:16 PM

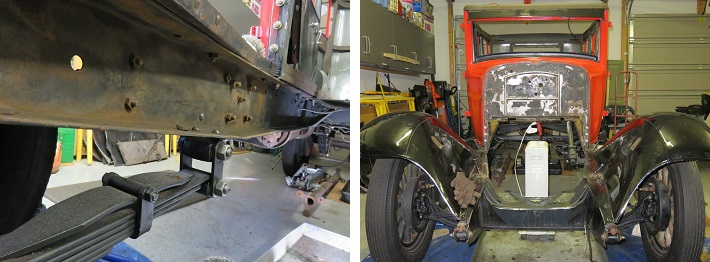

I'll check and see how many good ones I have. Some were prototypes that may not be good enough.

Quote from: frankp on December 17, 2017, 04:27:13 PM

Well done, Chet! Are you going to try a copper paint on the "silver" areas?

Quote from: ehenin on December 16, 2017, 06:03:50 PM

M. DE F. M.IND. RGTRDA.

Quote from: Articifer Tom on December 14, 2017, 06:09:08 PM

No middle of eastern Pa. Hour and half north of Hershey . You probably went up I 95 thur Jersey .