Quote from: Rusty on May 18, 2017, 11:16:03 PM

It sure looks that way. Was the inside body metal painted or just primed? Could the interior be painted black primer? Everything was painted, wood and metal. My car has a new interior but untouched mechanics.

Rusty,

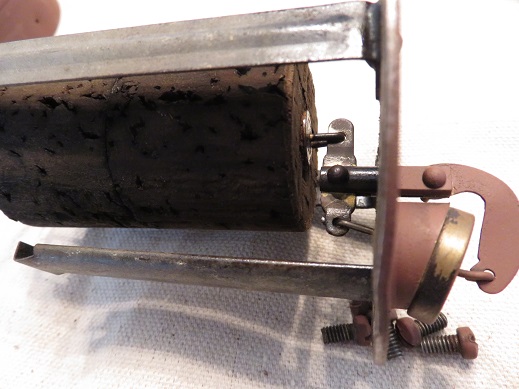

The untouched rear internal section of my car's metal skin was rusted. I would assume that when manufactured something was painted on the metal to help protect it from rust. Below is a picture before I started my work.

PS... I didn't worry about matching colors of paint and stain. Like John said.., nobody will ever see the work I am doing to the wood framing once the interior is reinstalled. I am however trying to duplicate the framing as close as possible to the original, without the assistance of the original technical drawings.