Running Board Redo February 3 - March 15, 2008

February 3, 2008

I started the refurbishment of my running boards. I

am using a good 3/4 inch exterior finished plywood. Also as Trim..,

aluminum cap moldings.

|

Parts List

-

23/32x2x4 Sand Pine

Plywood..................$ 16.53

-

2 Aluminum

Caps........................................$ 16.14

-

8 T-Nuts with prongs, 5/16 -

18x3.............$ 8.328

-

Hex Bolts 5/16 x 18 x 1"

...........................$ 2.08

-

1/8" Ribbed Rubber

material....................$ 55.00

Total Cost to date: $ 98.07

|

|

Step 1

-

I removed the old running boards and took careful

measurements.

-

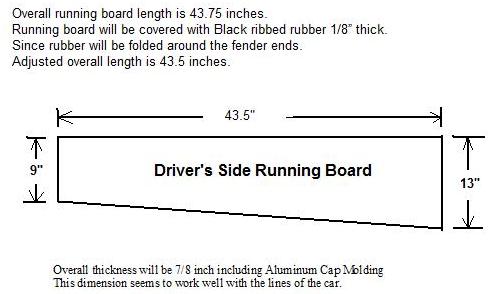

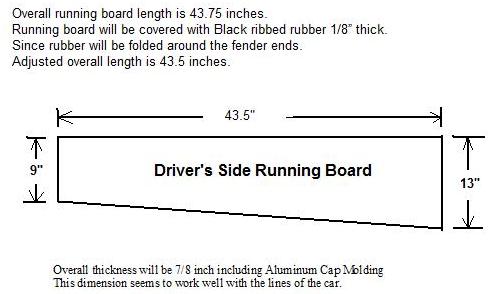

The measurements are typical from the driver's side

to the passenger side.

-

If you flip the diagram above it would be typical to

the passenger side board. The view to the left is the

passenger side.

-

At this point the overall thickness of 7/8 of an

inch seems correct..., of course if in the final assembly additional

thickness is needed I can always glue on an additional 1/8 or 1/4

inch ply to the bottom of the running board to ensure a clean fit.

If that is the case I will add the appropriate painted aluminum cap

to match.

|

|

Step 2

- I cut the boards and inserted Pronged T nuts so the board can be

bolted into place from under the car.

|

|

Step 3

- I drilled the surface with a 1 inch flat wood drill to ensure

that the T nuts were flat with the finished surface.

- When I glue on the rubber I will cover the T Nuts with masking

tap so that the glue doesn't get down into the nuts and push up on

the rubber surface when I screw the boards into place.

|

The work continues...

02/24/2008 |

|

|

Step 4

|

|

Step 5

-

I covered the pronged T nuts with tape to keep the

contact cement from getting into the threads.

-

I applied contact cement to the wood surface and to

the rubber mat.

-

Then I allowed the glue to dry and used a piece of

cardboard between the wood surface and the rubber mat . This

way I could position the rubber exactly where I wanted it.

-

I slowly pulled the cardboard out and allowed the

rubber to bond with the wood.

|

|

Step 6

-

Now the hard part. Fitting the trim.

Because of the irregular angles a miter box couldn't be used.

-

Originally I cut the wood boards to allow 1/8" on

each side for over lapping the rubber. Since I used the 1/16"

channels I needed to shim the aluminum end pieces out with 1/16"

shim stock.

-

I must say this was the hardest part of the project.

Getting the angles correct. The overall length was a perfect

at 43 & 3/4 inch

|

Well I think the finished product came out well and you can't

beat the price.

Saturday March 15, 2008

I installed my homemade running boards and I think they look A-OK. They

should serve me well until I can find some original parts at a reasonable price.