The Suspension

It was pointed out to me that the frames on the 29U when sitting on Jack Stands tend to bow in the middle. This would account for the problems with the doors closing while on the jack stands and especially with the rotten wooden interior structure. Based on this revelation I decided to work on ensuring that the front and rear suspension was in the best possible shape prior to reconstruction of the wood framing. Once the suspension is brought back to a reasonable and sound condition I will be able to allow the car to rest on its suspension and use jacks only to firm up the chassis while I fit the wooden frame and body parts. This way, when sitting on its normal suspension the stress on the frame parts should be at minimum. Also once aligned the hope is that it will stay in an aligned state after all the work is completed and the car rests on its normal road worthy suspension.

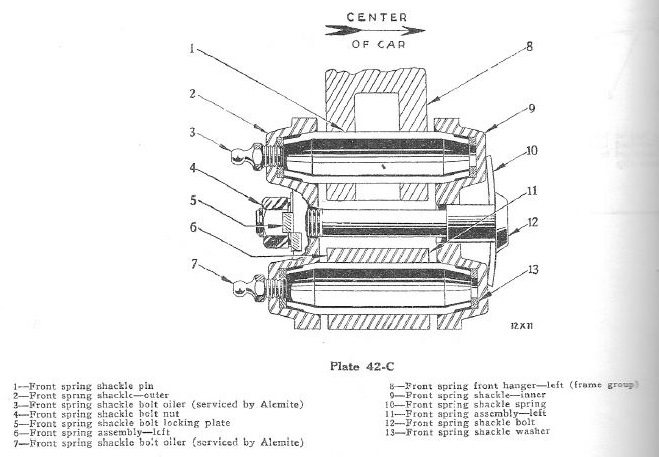

The Front Suspension

After 80 plus years I felt the need to completely check all front suspension components. My front springs are in very poor condition. The passenger spring has a broken leaf and missing the front upper dampening spring. The Driver's side sits lower than the passenger side even with the passenger spring having a broken leaf.

I contacted EATON Detroit Spring and they will be able to make a duplicate set of springs for me. The cost is in the six hundred dollar range for both front springs. I felt this was well worth the cost since these front springs have been carrying the full weight of the chassis and motor for the past 87 years. The replacement of these items will greatly improve the way the car sits on the road as well as how stable the body will remain aligned with the metal frame and wood structure. So far things sound simple but with cars of this age and rarity, nothing is simple especially when you are trying to acquire parts. If you have a Modal A Ford you can purchase just about anything but if you have anything else; you will need to be a great detective, fabricator, and innovator. My goal is always to do no harm to the original components when trying to find a modern day part solution. What I mean is.., I will not modify any original component so that it can not be returned to its historic originality if and when an original part is found.

|

Of course I could have had the leaf springs manufactured to a size that would have been easier to find shackle parts for but in keeping with my Prime Directive of "Doing no harm". I choose to have the springs made exactly as originally constructed. This means a 3/4" front eyelet hole and a 7/8" rear eyelet hole.

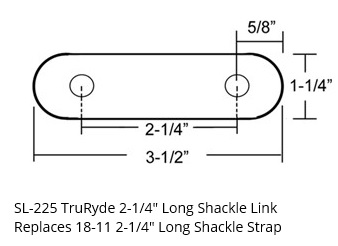

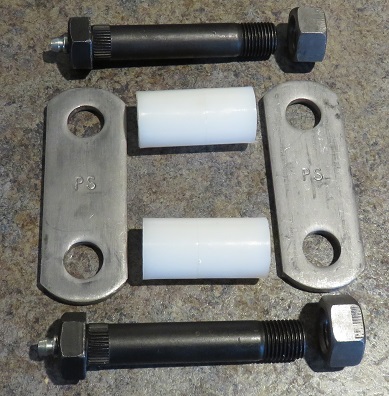

After much discussion with various venders and part restorers I stumbled across a fix that will maintain the historic integrity of my car and also produce a road worthy solution. I was able to find parts in a trailer store that met the requirements for a reasonable non-invasive fix.

|

The shackle Straps are a close match to the remains of the Tryon Shackle Straps.

|

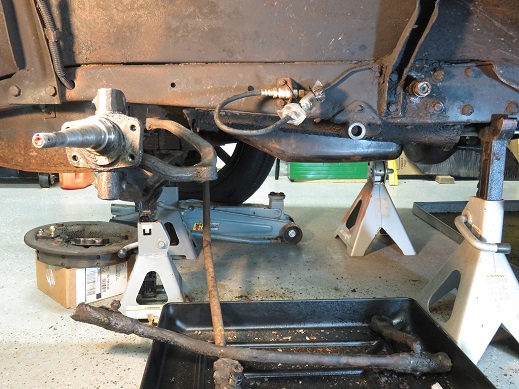

I spent a considerable amount of time removing the Tryon Shackle pins which were press fitted into both the spring and the frame support. Removing the pin from the spring was relatively easy in that I used a standard press but the frame support was another issue.

After 80+ years these pins did not want to budge. My saving grace was a 1940's Valve Guide Tool that I picked up in a antique store a number of years ago. Even with this very excellent tool the pin would not budge. I had to use a torch to heat the shackle support to expand the metal enough to allow the puller to extract the pin which was pressed in over 8 decades ago. As you can see below success was accomplished.

|

|

With the Shackle solution on the horizon I proceeded to

remove the damaged spring components. The

picture on the right is the leaf spring bumper. I sent this item to a part fabricator to be duplicated. The rubber is completely dried out and the bottom mounting plate is broken. This part will be recreated and re-volcanized at a cost of about $50 each. |

With the Shackle problem solved I proceeded to remove the Pitman arm and Draglink. All steering components will be cleaned and renewed to proper working condition.

Just to be on the safe side I tied the steering wheel in one position and marked the Pitman arm so that I can reinstall these parts in their correct positions. I don't think it will matter if I didn't do this but it is better to be safe than sorry. Especially with alignment issues.

|