March to May tying up loose ends.

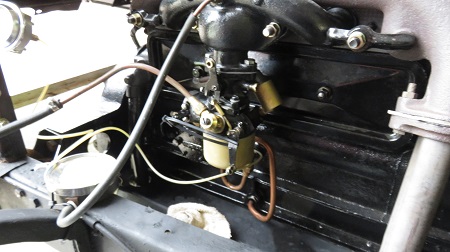

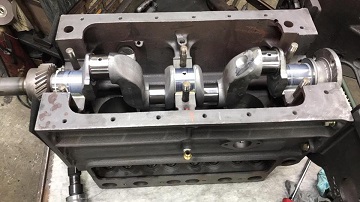

I have been working on the metal body work on and off over the past few months. Sometimes weather just didn't want to cooperate. My motor was finally returned to me after some needed rework to the main bearings to facilitate proper oil flow to the crank and connecting rods. Rework was done at no additional charge.

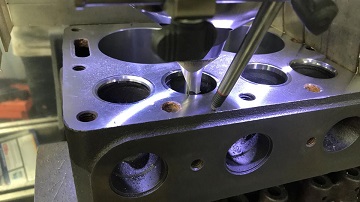

In a nutshell here is what was professionally done over the past 14 months to my motor:

|

Complete Rebuild

|

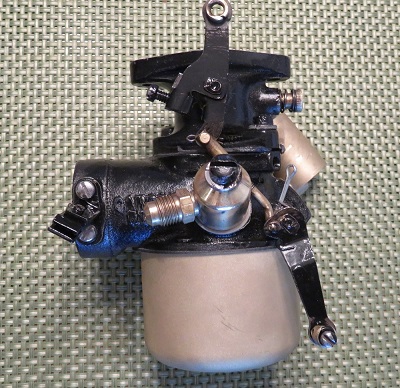

Besides the work that that was completed by the machine shop the following items were sent out for rebuild:

|

As of the writing of this page.., the Motor has about 5 hours of runtime and is running cool and strong. Vacuum and timing is excellent. 20.5 inches of Mercury. Clean exhaust.