Year 4 - Reassembly

Weather and rounding up parts is the agenda for the start of year four. It's hard at this point to move slowly because the natural instinct is to get the car back together and on the road again. It may be January but spring is on the horizon. This is a point where you are most likely to short cut the quality process for expediency. I need to resist the sprint to the finish line and concentrate on the finishing details.

The cold January weather has a tendency to slow things down. You find, as you pull together the old parts for the reassembly that in most cases they all need some type of restoration or in the very least a good cleaning/polishing, or maybe some touch up paint. Painting can be especially challenging even if just painting some screw heads to blend in with the final finished look. In my case, small items painted in less than accommodating temperatures are immediately brought into the house to dry in a warm dry place. Applying multiple coats can be a multi day process to ensure that the paint is properly cured before use.

My first task for the year was installing the rear fenders. I used the old fender welt to cut screw slits in the new Black 3/16" bead vinyl welting.

|

I purchased 1/16" thick rubber stock and

will be using this to make gaskets for any parts attaching to

painted surfaces. The picture to the left shows the gasket I made to attach the rear lamp assembly to the rear fender. Making the gaskets is very easy just trace the fixture and mark for the needed holes. I have different size hole punches that can be used for light metals and leather. Having the hole punches really makes for nice finished gasket. |

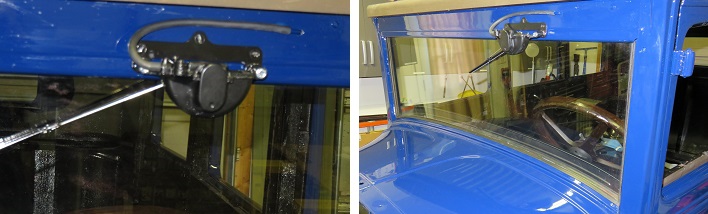

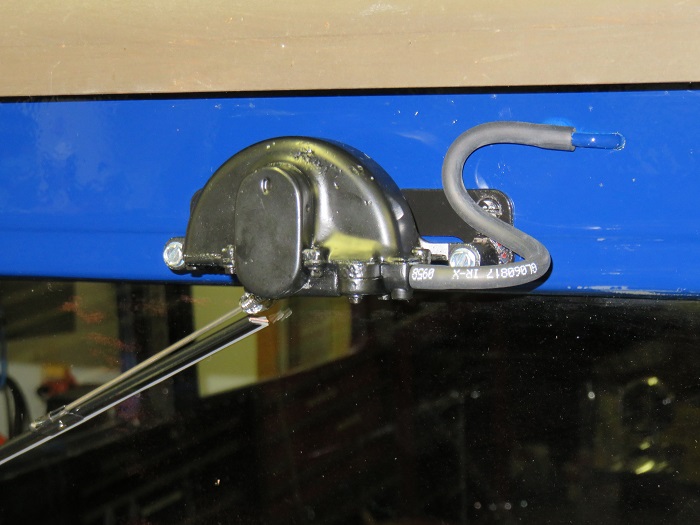

Before installing the front fenders I wanted to work on getting the windshield installed and get the windshield wiper working for the first time. The wiper motor that came with my car is cast iron. I tried to have it repaired but nobody would touch it not even the wiper man. So I am using an exterior mount Trico motor which fits Ford exterior mount cars 1929-31. Also using the same Ford 8" wiper blade and with a 6.750 length wiper arm. The 6 3/4" wiper arm with the 8" wiper blade is perfect for this car. Below is a picture of my original wiper motor on the right and the replacement I am using on the left.

I purchased this motor many years ago with the aspiration of installing it. Since I never took the car out in the rain I never found the need to fix the wiper. The state of Delaware requires a working windshield wiper. Since I have to have the car inspected there is no time like the present to get this item fixed. The mounting bracket that worked for my old wiper motor also works for the Trico wiper motor. This Trico KCX-1 motor has an exterior on/off slide. I will most likely leave the slide in run position and use the interior on/off valve to turn the wiper motor on/off.

In order to get this wiper motor installed I will have to install the windshield. It's a good thing the wife decided to look under the bed in the guest room because that's where the windshield was hiding out. If she didn't do this it might have taken days to find it. My advise to anyone embarking on a project like this is to make an inventory list showing where you put things. Finding them after a few years might be very challenging.

|

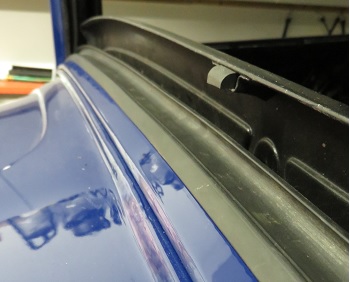

The first step in installing the windshield

is to install the rubber gaskets. I even installed the little

center bumper that I made from some leftover rubber stock.

It's always good to save things because you never know when you

might need them. Of course if your pile of stuff gets bigger

than your project it might be time to clean out the garage. Note: When you install the glass both doors need to be open and the left and right window slides can be taped to the glass. With the upper riser assembly removed install the glass. There should be nothing on the side wood frames to inhibit the windshield from going in. The left and right slides can be tacked into place after everything is installed and working properly. |

The windshield installed without issue and the wiper assembly works great. The pictures below are the finished product but the reflections from the glass and the paint make it a little hard to get a good picture. The car will look much better after the roof is done and the front hood is installed over the windshield.

It appears that I installed the motor upside down. I corrected this, see picture below:

It still works great !!

Well I have plenty to get to, door glass, fenders, bumpers, headliner, then I can have the roof done.