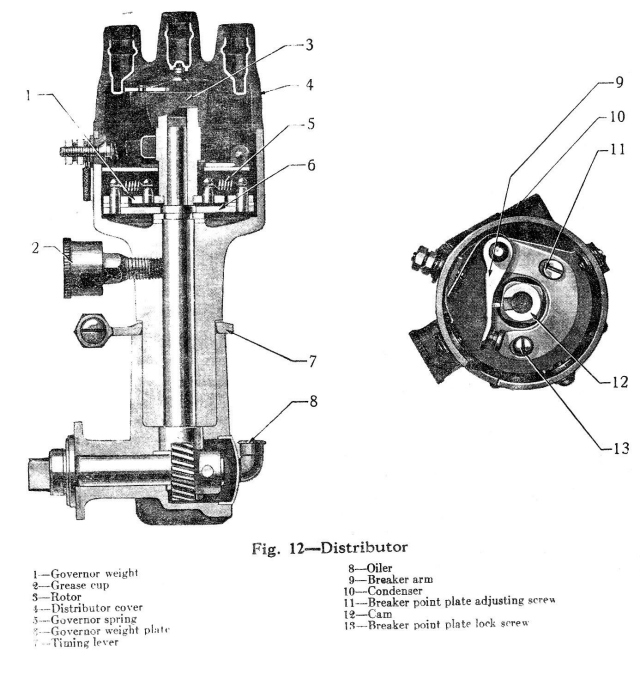

Distributor - 1929 Model U

The distributor, which is of the single breaker arm type with condenser on the outside of the base, is accessibly mounted above the timing gear case and driven through a shaft from the camshaft. The opening of the breaker points by the cam on the distributor shaft interrupts the flow of primary current, which induces an electro-motive force in the secondary winding of the coil, mounted on the dash. The high-tension current is delivered to the center terminal of the distributor cap, and thence through the rotor to the spark plugs. The cylinders are fired in the order 1-3-4-2.

To Adjust Point Opening

The rotor should be removed and the engine turned until the breaker arm rests on a high point of the cam. The gap should be .020" and may be measured by standard feeler gauges. If necessary to correct the adjustment of the gap the lock screw on the contact plate should be loosened and the adjusting screw turned as required. (Fig. 12.) The breaker arm should move freely on its pivot and it is advisable to check the tension of the breaker arm spring.

Ignition Coil

The ignition coil needs little attention other than to be kept clean, dry, and well grounded. All terminals on the coil must be tight.

Spark Plugs

The gap between the spark plug points must be .027" to .030". Too wide a gap will cause misfire, especially at high speeds and when laboring with open throttle, while a small gap causes poor idling. Dirty or fouled spark plugs should be washed in gasoline. Uniform gap setting insures evenness of engine firing.

The porcelain on the top of the spark plugs should be kept clean at all times. Oil or dust on the porcelain will cause leakage of the spark and in damp weather may prevent starting. Present day engines develop high compression and very high speed. This severe duty imposed on the spark plugs causes erosion. It is, therefore, advisable to replace spark plugs at intervals of every 10,000 miles of service. The installation of new spark plugs, properly adjusted, will have a marked effect upon the performance of the engine and aid materially in keeping the engine in condition for smooth flowing maximum power.

The engine performs best with the spark plugs furnished with the car. These are obtainable from Plymouth Service Stations and should be used to the exclusion of all others. The use of so-called carbon-proof spark plugs and others having smaller diameter electrodes should be avoided. Such spark plugs will cause the engine to miss on heavy pulls.

Suggestions

Ignition trouble will make itself known by the engine misfiring or refusing to start. If the engine misses regularly on one cylinder, the trouble is usually clue to the spark plug in that cylinder being dirty, broken or improperly adjusted. If misfiring is not limited to one cylinder, the cap should be removed from the distributor and the contact points examined to make certain that they make good contact with each other and are clean. The correct point opening is .020". If the contacts show a tendency to burn, the distributor may not be well grounded to its mounting bracket. Paint and dirt should be scraped off the bracket to insure a good ground. The condenser, which is on the distributor, should be tested and its connections from the distributor should be tight. When the engine will not start, the ignition should be checked as follows:

The ignition switch should be turned "on" and the cap removed from the distributor to see that the contact points are touching each other. Then the secondary wire should be disconnected from the center terminal of the distributor cap and held about 1/8" from some metal part of the engine. The contact points should next be separated by moving the breaker arms with the fingers. A spark should jump between the end of the high-tension cable and the metal part of engine, if the coil and its connections are in good condition. If no spark is obtained under the above conditions, it should be determined whether current passes through the coil.

A quick check may be made on the primary circuit of the coil by closing the ignition switch and cranking the engine. If the ammeter needle moves bark and forth between 0 and 3 or 4 amperes discharge, it indicates the primary circuit is all right. If ammeter needle does not move, the following procedure should be observed:

With the ignition switch turned "on" and the distributor contact points separated, a screwdriver should be rested over the edge of the distributor housing with the end of the screwdriver touching against the breaker arm. There should be a flash or spark to indicate the flow of current. If current flows, the secondary winding of the coil is apparently damaged and a new coil should be installed. If no current can be detected on this test, the small wire from the coil to the distributor should be examined for breaks, loose connections, or damaged insulation. If the wiring is in good condition it should be determined whether the current reaches the coil. A screwdriver should be rested over the "Bat" terminal of the coil and at the same time touch some metal part of car with the end of the screwdriver. If a flash or spark is obtained, the coil is faulty and a new one should be installed. If no current reaches the coil, the trouble is due to a loose connection, broken wire, defective switch, dead battery, or poor ground connection.

To Set Ignition Timing

The breaker points should be adjusted to .020" opening and the manual spark control lever set in the fully advanced position. The crankshaft should be rotated until No. 4 piston is going up on exhaust stroke and stopped when the piston is .050" before top dead center. The bolt which clamps the distributor timing lever to the distributor should be loosened and the distributor cap removed to see that the rotor brush is at No. 1 spark plug cable terminal. The distributor should next be rotated in an anti-clockwise direction, as viewed from above, until No. 1 cam begins to separate the breaker points. When doing this the distributor rotor should be pressed against the direction of rotation to be certain that all backlash is removed. The clamp screw should then be tightened and the distributor cap reinstalled as well as the spark plug cables connected to the proper spark plugs and terminals on the distributor cap. The spark control button on the instrument panel should be checked for full advance and retard.

Firing Order

The firing order of the cylinders is 1-3-4-2. The wires from the spark plugs should be connected to the terminals on the distributor corresponding with the number of the cylinder in which the spark plugs are placed. Number 1 cylinder is nearest the radiator. The wiring diagram (Fig. 9) indicates the location of the distributor terminals for the different spark plugs.

Spark Advance

For all ordinary road driving the spark control button should be in the advanced position, which is all the way in to the instrument panel. When pulling hard with a wide open throttle, but not at high vehicle speed, t he spark should be retarded by pulling the control button about half way out. When cranking the engine by hand, the spark control button should be all the way out. The automatic advance will take care of all other conditions.